Welcome to Cogeneration.Pro, an online resource for the Cogeneration industry.

To learn more about Cogeneration technology click the following links:

An Engineer's Note Book

Welcome to Cogeneration.Pro, an online resource for the Cogeneration industry.

To learn more about Cogeneration technology click the following links:

The traditional power grid is a centralized model, consisting of a complex network of power lines that transmit and distribute electrical power generated at central power stations to the end-users. From the power plants, electricity is stepped up to high voltage (500kV, 275kV, 132kV) and injected into the transmission lines which transport electricity over long distances. At the end of the transmission lines are the distribution sub-stations which step down the electricity to medium and low voltage (33kV, 22kV, 11kV, 400V/230V) for distribution to end-users.

Cogeneration or Combined Heat and Power (CHP) is a sustainable energy solution that provides numerous benefits to a variety of stakeholders, including increased energy efficiency, lower emissions, attractive economic returns, and increased power system resiliency. The technology is a low carbon intensity and high-efficiency solution for the simultaneous generation of electricity and thermal energy. It is a proven, cost-effective, and readily available technology. (Cogen Europe, 2010). The adoption of cogeneration systems for industries that have combined demand for heat and power is envisaged to improve energy efficiency and security of power supply while reducing emissions/pollution, in addition to many other benefits as described in the following sections.

In the traditional or conventional system of power generation, industrial plants which require both electrical power and thermal energy will import electricity from the power grid and generate heat on-site using boilers. This arrangement is suboptimal because there are considerable energy losses associated with the power grid, and the combined generation efficiency of imported power and self-generated heat is considerably less than that of a cogeneration plant.

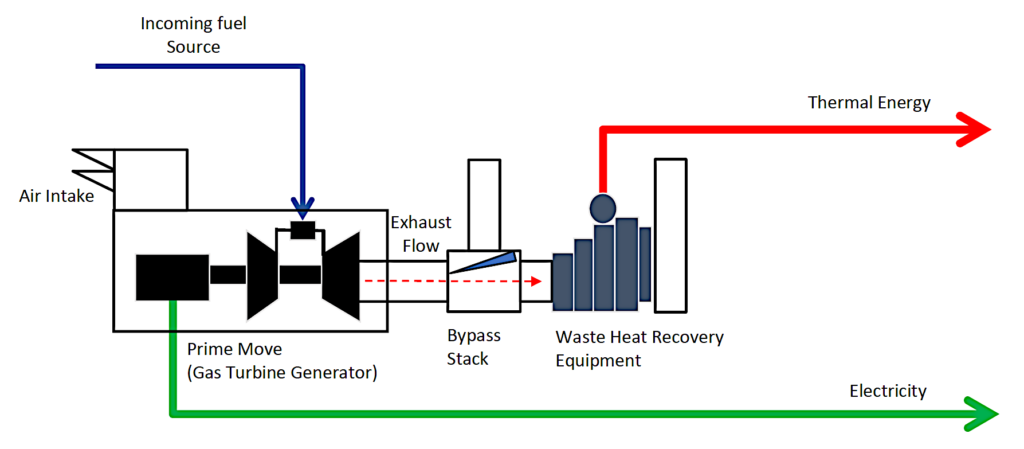

A cogeneration system consists of the following key components:

Cogeneration is the simultaneous production of electricity and useful thermal energy from a single source of primary energy. It is widely recognized as a high-efficiency smart solution for decarbonizing energy-intensive industries which have combined demand for electricity and thermal energy.

Natural Gas is the cleanest fossil fuel for Cogeneration systems. Different Cogeneration system configurations have been devised to work with different types of fossil fuels, ranging from natural gas & fuel oil to coal. Nevertheless, Natural Gas is undisputably the cleanest fuel option available in terms of Carbon Dioxide (CO2) emissions.

Cogeneration, or Combined Heat and Power (CHP), is generally defined as the simultaneous generation of electricity and useful thermal energy (usually in the form of steam, hot water or chilled water) from a single source of primary energy.